When it comes to cargo transport, securing your load is not just a matter of efficiency, safety, and protection—it’s a legal requirement. Chains and binders ensure loads of all sizes and weights remain stationary and secure during transit. This article delves into the critical role of chains and binders, their types, and how to select the right ones for your transport needs.

Understanding Chains and Binders

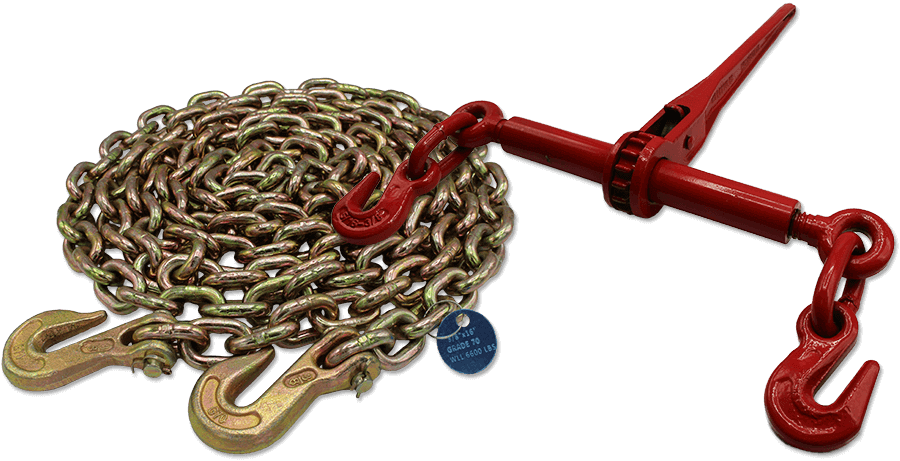

Chains and binders are integral components of a cargo securement system. They are used to tie down heavier loads on flatbed trailers, ensuring that the cargo doesn’t shift or fall off during transportation. The robustness, reliability, and long-lasting attributes of chains and binders make them a preferred choice for heavy-duty applications.

Types of Chains

The most common type of chain used in cargo securement is the Grade 70 transport chain, also known as G70. This chain is specifically designed for load binding and is made of high strength carbon steel.

For even heavier loads, Grades 80 and 100 can be used, as these are made of higher strength alloy and are specifically designed for overhead lifting applications where, if dropped, the load could cause bodily or property damage. Of course, the higher you go up in the standards, the more expensive the chains become.

The National Association of Chain Manufacturers, or NACM, has documented the requirements of the various grades as mentioned above. The NACM Welded Steel Chain Specifications can be found at their website by following this link: https://www.nacm.info/specifications/welded-chain-specifications/

Note that all chains are embossed with their grade in an appropriate manner, at specific lengths, so that you can easily know the grade of chain you’re using.

Types of Binders

Binders, also known as load binders or chain binders, are devices used to tighten the chains around the cargo. There are two primary types of binders:

Ratchet Binders: These binders use a ratcheting mechanism to tighten the chain. They provide a mechanical advantage, making it easier to apply significant tension with minimal effort.

Lever Binders: Lever binders, also known as snap binders, use leverage to tighten the chain. They are quicker to apply than ratchet binders but require more strength to operate.

Selecting the Right Chains and Binders

When selecting chains and binders, it’s crucial to consider the following factors:

Weight of the Load: Ensure that the Working Load Limit (WLL) of the chains and binders is not exceeded by the cargo’s weight.

Type of Cargo: Different types of cargo may require different securement methods. Abrasive or sharp-edged loads might need additional protection to prevent the chains from being damaged. This is where our corner protectors come into play.

Length and Diameter of the Chain: The length of the chain should be sufficient to secure the cargo properly, and the diameter should correspond to the WLL required for the load.

Compatibility: Chains and binders are rated with different grade numbers, indicating their strength and load capacity. It’s imperative to use chains and binders of the same grade. Pairing a higher-grade binder with a lower-grade chain can result in the underutilization of the binder’s capacity, while the opposite can lead to chain failure.

Additionally, the size of the hooks on the binders should match the diameter of the chain links.

When you purchase, it’s best to buy a transport chain that has hooks already included on both ends, and then supplement length with a chain that is a higher grade than the one with the hooks.

Verduyn Tarps carries a wide range of chains and binders that satisfy the above requirements. Click here to discover them and other products that go along with them!

Safety Considerations

Safety is paramount when using chains and binders. Always inspect the chains and binders for any signs of wear, damage, or deformation before use. Damaged equipment should be replaced immediately to prevent accidents. Additionally, ensure that the chains and binders are properly tightened and secured to prevent the load from shifting during transport.

The adage “measure twice, cut once” applies here. Make sure you double-check the security of the load and where the chains are securing the load.

Maintenance and Care

Proper maintenance can significantly extend the life of your chains and binders. Regularly clean them to remove dirt and grime, and lubricate the moving parts of binders to ensure smooth operation. Store them in a dry place to prevent rust and corrosion.

Regulatory Standards and Compliance in Canada

There are strict regulations that govern cargo transportation in Canada. These regulations ensure efficiency and safety. There are national standards set out, highlighting the importance of vehicle maintenance, driver responsibilities, and load securing.

Rules will depend on different types of cargo such as oversized loads, temperature sensitive goods, and hazardous materials. Being compliant with these regulations is important not only for legal operation, but also for safety and protection.

Truck operators must keep track of updates and regional variations, to ensure adherence to protocols. When transporting heavy loads, chains and binders play a major role in ensuring safety.

Proper Use of Binders: Techniques and Safety Tips

Binders play an important role in keeping cargo safely in place. Correct techniques have to be employed so the cargo load is evenly distributed. These techniques involve checking binder tension and using appropriate tie-down points. The use of ratchet and lever binders are common practice.

These accessories, however, must be handled carefully to prevent injury. When securing heavier or demanding loads, drivers and operators need durable accessories with greater strength. Chains are paired with binders to help keep cargo in place.

Common Mistakes to Avoid

Mistakes are preventable when operators apply proper safety measures.

Uneven weight distribution is one of the most common errors drivers encounter. Avoid using improperly sized chains or worn binders as these can lead to equipment failure or load shifts. This error impacts the vehicle’s balance and control.

If drivers use damaged equipment when securing cargo, such practice can also pose serious problems to the cargo.

Pay attention to legal load limits to avoid the risk of fines and accidents. Load checks and document inspections help avoid putting the driver and operator at risk.

The Importance of Ongoing Training

For anyone involved in transporting and securing cargo, ongoing training is a must. Regulations and equipment evolve and taking refresher courses help ensure that drivers and operators are up to date with the legal requirements and latest safety standards.

Drivers also need to undergo training to correctly use chains and binders to properly transport heavy-duty or oversized loads. Ongoing training also helps drivers and operators stay compliant, equipped, and safe.

Conclusion

Chains and binders are essential tools in the cargo transport industry, providing the necessary strength and reliability to keep heavy loads secure. By understanding the different types of chains and binders, and selecting the right ones for your needs, you can ensure the safety of your cargo and comply with transportation regulations. Remember, the security of your load is only as strong as the chains and binders you use.

Incorporating chains and binders into your cargo securement routine is not just a best practice—it’s a critical step in safeguarding your cargo, your vehicle, and the safety of others on the road. Make sure to choose the right chains and binders for your transport needs, and always prioritize safety and compliance in every aspect of transporting your cargo.

Our experts here at Verduyn Tarps can help you figure out exactly what you need. Call us at the number at the top of the page, or contact us today!